I-Metal graphite ingahlukaniswa ibe yi-copper base metal graphite, i-aluminium base metal graphite, i-iron base metal graphite kanye ne-nickel base metal graphite ngokusho kwezinhlobo ezahlukene zensimbi. Izinhlobo ezahlukene ze-metallic graphite zinezakhiwo ezihlukene zomzimba namakhemikhali futhi zifanele izinkambu ezihlukene zokusebenzisa.

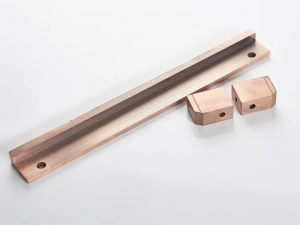

I-graphite yensimbi yesisekelo se-Copper: ene-conductivity ephezulu yokushisa namandla aphezulu emishini, ifaneleka ku-high-temperature exchanger heat, condenser, heater kanye nezinye izinto zokusebenza.

I-aluminium base metal graphite: ene-low density, ukumelana nokugqwala, ukuhanjiswa okuphezulu nezinye izici, ilungele izindiza, i-aerospace, izimoto nezinye izinkambu.

I-iron base metal graphite: enamandla amakhulu, ukuqina okuphezulu, ukumelana nokugqoka okuphezulu nezinye izici, ilungele ukukhiqizwa kwemishini, ukwakhiwa kwemikhumbi neminye imikhakha.

I-graphite yensimbi esekelwe ku-nickel: Inokumelana nokushisa okuphezulu, ukumelana nokugqwala, amandla aphezulu nezinye izici, futhi ifanele ukuhamba kwezindiza, i-aerospace, imboni yenuzi neminye imikhakha.

Inqubo yokulungiselela i-metallic graphite ikakhulukazi ihlanganisa indlela eyinhlanganisela yokucindezela okushisayo, indlela yokuhlanganisa i-arc kanye nendlela yokubeka umhwamuko wamakhemikhali. Phakathi kwazo, indlela ehlanganisiwe yokucindezela ukushisa iyindlela esetshenziswa kakhulu.

Izinyathelo zokulungiselela i-metallic graphite ngendlela ehlanganisiwe yokucindezela ukushisa zimi kanje:

1. Yenza ishidi lensimbi neshidi legraphite libe yisimo esidingekayo nosayizi.

2. Hlela ishidi lensimbi ne-graphite sheet ngesilinganiso esithile.

3. Faka inkimbinkimbi ye-metal-graphite emishinini yokucindezela okushisayo ukuze uthole izinga lokushisa eliphezulu nokucindezela okuphezulu kokucindezela okushisayo.

4. Khipha i-graphite yensimbi ecindezelwe ngokushisayo ukuze icutshungulwe ngokulandelayo, njengokupholisha nokusika.

1. I-conductivity ephezulu: i-graphite yensimbi ine-conductivity enhle kakhulu futhi ingasetshenziswa ukwenza izingxenye zikagesi ezifana nama-electrodes, ama-heaters kagesi, ama-solenoid valves, njll.

2. Ukushisa okuphezulu kwe-thermal: i-graphite yensimbi ine-conductivity enhle yokushisa futhi ingasetshenziswa ekushintsheni ukushisa okushisayo, ama-condensers, ama-heaters nezinye izinto zokusebenza.

3. Ukuqina kokushisa okuphezulu: i-graphite yensimbi inokumelana ne-oxidation ephezulu kanye nokumelana nokushisa okuphezulu, futhi ingasebenza ngokuzinzile ngaphansi kokushisa okuphezulu isikhathi eside.

4. Ukumelana nokugqwala: i-graphite yensimbi inokumelana nokugqwala okuhle kakhulu futhi ingasetshenziswa ukwenza iziqukathi zemidiya ezonakalisayo kumakhemikhali, ekhemisi nakweminye imikhakha.

5. I-coefficient ephansi yokwandisa okushisayo: i-graphite yensimbi ine-coefficient ephansi yokwandisa okushisayo, okunganciphisa ukuguqulwa kwemishini kanye nomonakalo obangelwa ukushintsha kwezinga lokushisa.

I-Metallic graphite isetshenziswa kabanzi kwezensimbi, ukukhiqizwa kwemishini, izindiza, imboni yamakhemikhali, i-electronics, imithi, ukwakhiwa kanye neminye imikhakha. Izindawo ezithile zohlelo lokusebenza zifaka:

1. Amadivayisi anezinga lokushisa eliphezulu: njenge-heater, i-heater, i-vacuum furnace, isithando somlilo esincibilikisayo, njll.

2. Iziqukathi zemidiya ezonakalisayo: njengezinsimbi eziphendulayo, amathangi, amapayipi, njll. ezintweni zamakhemikhali.

3. I-Aerospace, imboni yenuzi: njengama-blade enjini, izihlanzi zomoya, izinto ze-nuclear reactor, njll.

4. Izinkambu ze-elekthronikhi nezikagesi: njengamapuleti e-conductive, izinto zokuvikela, izinto ze-semiconductor, ama-electrodes, njll.

5. Inkambu yokukhiqiza imishini: njengezigxivizo zemishini, amathuluzi okusika, ama-bearings, njll.