I-graphite ehlanganisiwe yethusi yenziwe ngezinhlayiya ze-graphite nezethusi. Phakathi kwazo, i-graphite iyinhlangano ye-carbonaceous, engahlukaniswa ibe i-graphite yemvelo kanye ne-graphite yokufakelwa. I-crystal ifomu le-graphite yemvelo iyishidi le-hexagonal, eline-crystallinity ephezulu kanye ne-thermal conductivity ephezulu. Kuyinto enhle kakhulu ye-thermal conductivity material. I-graphite yokwenziwa ilungiswa ngokuyinhloko yi-high-temperature sintering nezinye izinqubo, futhi inezici ze-homogeneity enhle namandla aphezulu.

Izinhlayiya zethusi zihlanganisa ithusi ne-graphite ngenqubo ethile ukuze zenze i-graphite efakwe ngethusi. Ukuba khona kwezinhlayiya zethusi akukwazi nje ukuthuthukisa ukuqhutshwa kwe-graphite, kodwa futhi kuthuthukise amandla ayo nobulukhuni, ngaleyo ndlela kuthuthukise izakhiwo zayo zemishini nokumelana nokugqoka. Ngaphezu kwalokho, izinhlayiya zethusi zinganciphisa ngempumelelo ukumelana ne-graphite futhi zithuthukise ukuqhutshwa kwayo okushisayo.

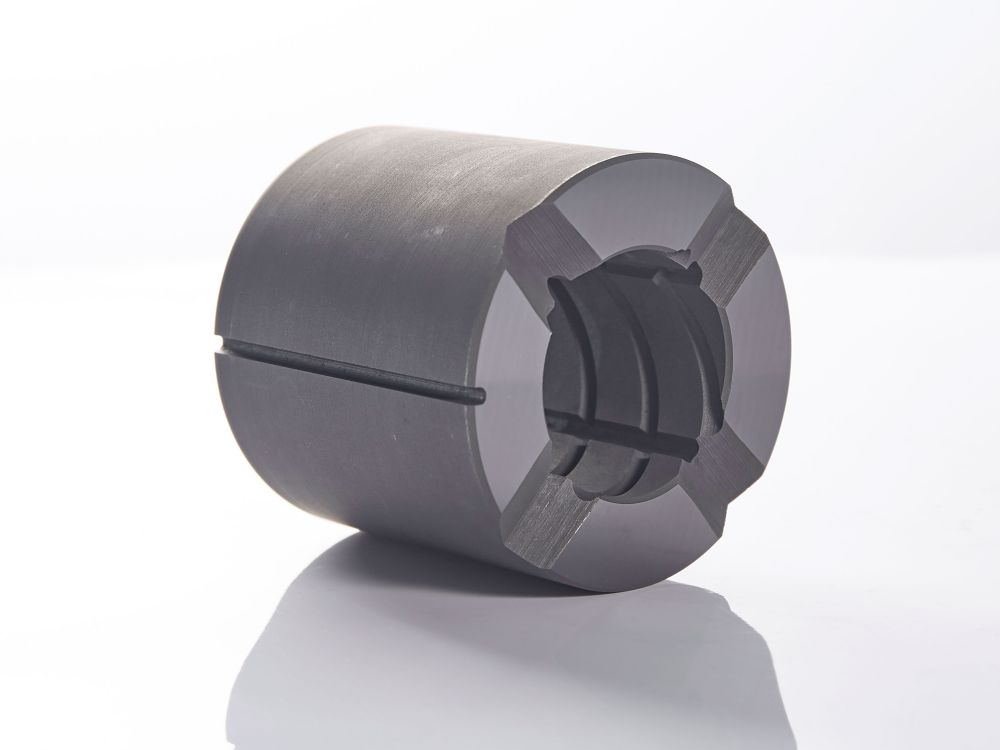

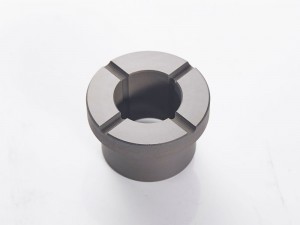

Amafomu omkhiqizo we-graphite efakwe ngethusi ahlukahlukene, angahlukaniswa abe ipuleti, ipayipi, impushana nezinye izinhlobo.

I-Plate ingenye yezinhlobo ezivame kakhulu zomkhiqizo. Yenziwe nge-graphite ne-powder yethusi ngenqubo yokucindezela ukushisa okushisayo. Ubukhulu ngokuvamile buphakathi kuka-1mm no-6mm. Ubude nobubanzi kungenziwa ngokwezifiso ngokwezidingo zangempela. Ingaphezulu lepuleti libushelelezi futhi lifana, futhi lingenziwa ngomshini, licutshungulwe futhi lihlatshwe ukuze lihlangabezane nezidingo zezinhlelo zokusebenza ezahlukene.

Ipayipi lakhiwe nge-extrusion ngemva kokuxuba izinhlayiya ze-graphite nezethusi. Izindawo zayo zangaphakathi nezingaphandle zibushelelezi futhi zifana. Ingacutshungulwa ngezimbobo zangaphakathi kanye nezindawo zangaphandle zokukhiqiza ama-electrode, ama-capacitor, ama-transformers afakwe uwoyela ane-voltage ephezulu kanye namanye amadivaysi.

I-powder yenziwe ngezinhlayiya ze-graphite nezethusi ngokusebenzisa inqubo yokugaya ekhethekile. Ubukhulu bezinhlayiyana zempushana zingashintshwa ngokuvumelana nezidingo zangempela. Inamaphuzu amaningi okuxhumana kanye nokuziphatha okuhle. Ingasetshenziswa kabanzi kumishini kagesi, izinto zebhethri neminye imikhakha.

Inqubo yokukhiqiza i-copper graphite ilula, ngokuvamile ihlanganisa lezi zinyathelo ezilandelayo:

1. Izinto zokulungiselela: i-powder yethusi ne-graphite powder izoxutshwa ngesilinganiso esithile, futhi inani elithile lokugcoba kanye ne-binder liyongezwa.

2. Ukulungiswa komzimba obumbayo: cindezela izinto ezixubile zibe umzimba obumbayo ofanele ukucutshungulwa.

3. Ukomisa nokucubungula: yomisa ukubumba, bese ucubungula, njengokujika, ukugaya, ukubhola, njll.

4. I-Sintering: i-sintering izingxenye ezicutshunguliwe ukuze zenze into eqinile ye-graphite yethusi.

Izici eziyinhloko ze-graphite efakwe ngethusi yilezi ezilandelayo:

(1) I-conductivity enhle: i-graphite efakwe ithusi iqukethe izinhlayiya eziningi zethusi, okwenza ukuqhuba kwayo kube kuhle kakhulu.

(2) Izakhiwo ezinhle zemishini: ukuba khona kwezinhlayiya zethusi kuthuthukisa amandla nobulukhuni be-graphite, okwenza kube nezakhiwo ezinhle zemishini.

(3) Ukumelana okuhle kokugqoka: ukuba khona kwezinhlayiya zethusi nakho kungathuthukisa ukumelana nokugqoka kwegraphite.

(4) Ukumelana nokugqwala okuhle: igraphite ngokwayo inokumelana nokugqwala okuhle. Ngokungezwa kwezinhlayiya zethusi, ukumelana kwayo nokugqwala kuhle kakhulu.

(5) I-conductivity enhle yokushisa: i-graphite iyinto enhle kakhulu ye-thermal conductivity. Ngemuva kokwengeza izinhlayiya zethusi, ukuqhutshwa kwayo okushisayo kungcono nakakhulu.

I-graphite ye-Copper-impregnated ine-conductivity enhle kakhulu kanye nezakhiwo zemishini, futhi isetshenziswa kabanzi ezintweni zebhethri, ukuphathwa kwe-thermal, amadivaysi kagesi, ukukhiqizwa kwemishini kanye neminye imikhakha.

Emkhakheni wezinto zebhethri, i-graphite efakwe ngethusi isetshenziswe kabanzi ekulungiseleleni amapuleti e-electrode yebhethri ukuze kuthuthukiswe ukusebenza kwamabhethri ngenxa ye-conductivity yayo enhle kakhulu kanye nezakhiwo zemishini.

Emkhakheni wokuphatha okushisayo, i-graphite efakwe ngethusi ingenziwa ibe ukushisa okuqhuba amaphiko okuchithwa kokushisa kwemishini ehlukahlukene ye-elekthronikhi. Ngenxa ye-conductivity yayo enhle kakhulu yokushisa, ingakwazi ukuqeda ukushisa ngokushesha, ngaleyo ndlela iqinisekise ukusebenza okuzinzile kwesikhathi eside kwemishini.

Emkhakheni wemishini ye-elekthronikhi, i-graphite efakwe ngethusi ingasetshenziswa ukwenza ama-capacitor, ama-transformer afakwe uwoyela ane-voltage ephezulu kanye namanye amadivaysi. Ngenxa ye-conductivity yayo enhle, ingakwazi ukudlulisa ngokuphumelelayo izimpawu zikagesi namandla, ngakho ingakwazi ukuhlangabezana nezidingo zemishini ehlukahlukene kagesi.

Emkhakheni wokukhiqiza imishini, i-graphite efakwe ngethusi ingenziwa ibe yizimo ezihlukahlukene zamapuleti, amapayipi, ama-powders, njll, ukuhlangabezana nezidingo ezihlukahlukene zokukhiqiza imishini. Ngesikhathi esifanayo, ukumelana kwayo nokugqoka kanye nokumelana nokugqwala nakho kuyenza ibe yinto ekahle yokukhiqiza eyimishini.